Pet wet food is typically a mixture of puree, meat chunks, and gravy, with a thick consistency and potentially containing solid particles of varying sizes. This mixture can easily oxidize and spoil when exposed to air. During the filling process, stringing can occur, which leads to imperfect sealing of the bags, resulting in leaks. Therefore, it demands exceptionally high packaging seal integrity.

To address the challenges of automated packaging for pet wet food, we'd like to present to business owners our horizontal pre-made pouch packaging machine.

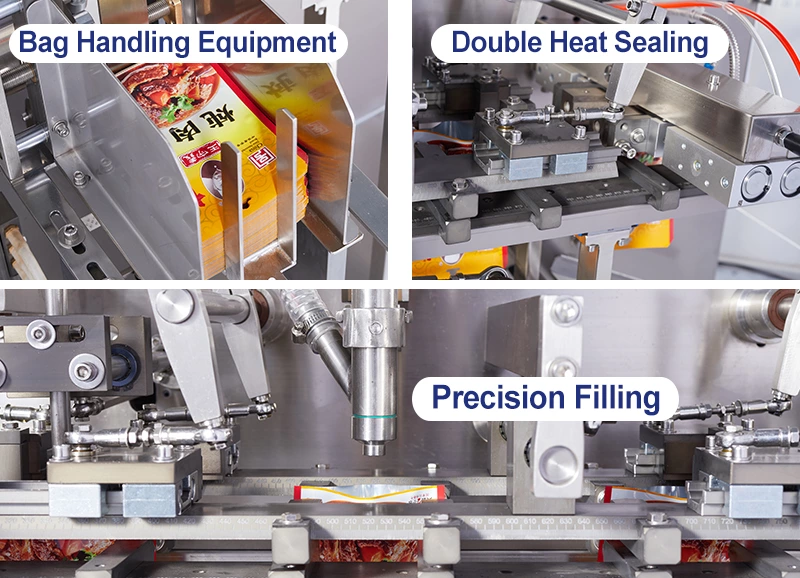

This equipment utilizes pre-made pouches for automatic filling. It employs a robotic arm for automatic pouch pickup and uses pneumatic principles for automatic pouch opening. The machine can inject nitrogen gas into the pouch, which helps extend the food's shelf life.

It is equipped with a servo-driven high-precision piston filling system. For sauces containing meat chunks, a hopper with a heated stirring function is available to prevent the separation of solids and liquids. The filling nozzle, with its food-grade 304/316 stainless steel contact parts, features an anti-drip device to ensure no stringing occurs during the filling process.

It is equipped with a servo-driven high-precision piston filling system. For sauces containing meat chunks, a hopper with a heated stirring function is available to prevent the separation of solids and liquids. The filling nozzle, with its food-grade 304/316 stainless steel contact parts, features an anti-drip device to ensure no stringing occurs during the filling process.

The machine automatically performs a double heat-sealing process, creating a complete and robust seal that guarantees a tight closure and prevents leakage.

From pouch pickup, opening, metered filling, gas flushing, double heat sealing, to finished product output, it achieves speeds of up to 65 bags per minute!

Based on the actual production needs for wet food products, options such as a date coder and a checkweigher are available.

Another significant advantage of this horizontal pre-made pouch packaging machine is its excellent compatibility, adapting to various mainstream pre-made pouch types on the market:

Aluminum Foil Pouches: Offer high barrier properties, providing protection against light, moisture, and oxygen. They are the premier choice for high-end wet food and functional treats.

Plastic Composite Pouches (e.g., PET/PE, NY/PE): Provide good barrier properties and toughness, offering a cost-effective solution suitable for most wet food products.

Retort Pouches: Can withstand high-temperature sterilization (above 121°C), used for wet food products requiring long-term ambient temperature storage.

This premade pouch packaging machine accommodates bag dimensions within a width range of 70-160 mm and a length range of 100-260 mm. The filling capacity range is 5-500 ml. Packaging speed ranges from 30 to 60 bags per minute. Air consumption is 0.7³/min. It uses pneumatic suction cups for bag grasping and requires an air compressor for operation.

We can provide OEM custom packaging machine services. If needed, please email me or leave a message. Thank you for your time!

E-mail: info@ksdmachine.com

Phone: +86 13726511228

WhatsApp: +86 13726511228