Quality Control

We maintain strict quality control at every stage, ensuring each product meets international standards. Advanced testing and inspection guarantee reliability, safety, and consistent performance.

At KUNSHIDA, we implement a rigorous quality control system that spans the entire manufacturing process. From the selection of high-grade raw materials to precision machining and final assembly, every step is meticulously inspected. Each machine undergoes real-world performance simulation and multi-point testing to ensure stable operation, accurate packaging, and long service life. This commitment to quality allows us to deliver equipment that consistently meets international standards and earns long-term trust from global clients.

100%

24/7

100%

We control quality from the source by carefully selecting raw materials and critical components to lay a solid foundation for overall machine performance.

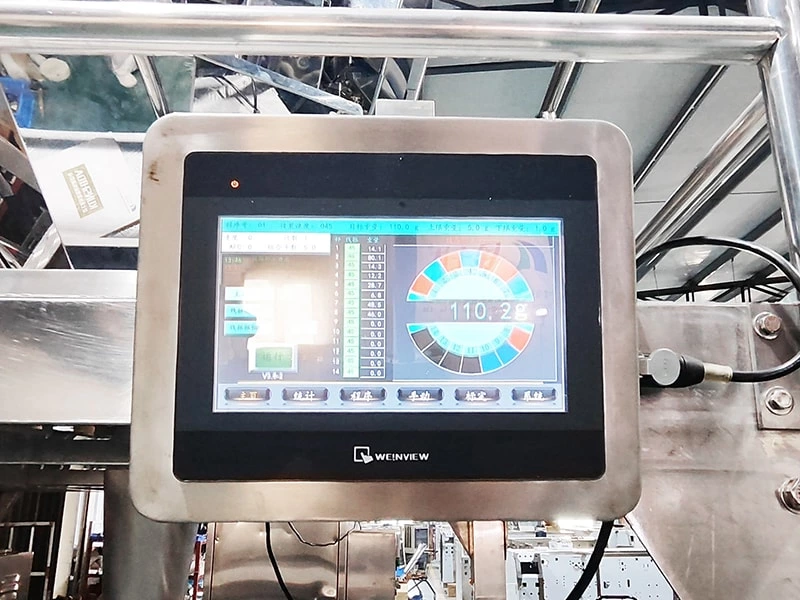

Every procedure follows standardized operating protocols, with digital monitoring systems ensuring precise and error-free assembly processes.

Each unit undergoes a complete series of functional and durability tests to guarantee stable operation and excellent customer experience.

Headquarters Address: No. 2, South Side Of Xilong Industrial Zone, Qishan Sub-district, Jinping District, Shantou City, Guangdong Province, China

Monday to Friday - 9:00 AM to 6:00 PM

Feel free to fill out our contact form below and our support team will get back to you within 24 hours.