Blended juice is far from being a simple blend of single juices. It is a carefully crafted combination of two or more fruit (or vegetable) juices, designed to achieve complementary and enhanced flavors and nutrition.

-

Nutrient-Rich, Yet Perishable: The combination of multiple fruits means a more complex profile of vitamins, minerals, and active enzymes. However, these very nutrients also make the product more susceptible to oxygen and light, leading to oxidation, browning, nutrient degradation, resulting in dull color and flavor loss.

-

Potential Pulp and Fiber Content: Many premium blended juice products emphasize "real fruit pulp" or "high fiber." These suspended solids present a challenge to a packaging machine's filling system, requiring it to be smooth, clog-resistant, and capable of preserving the product's textural integrity.

-

Diverse Product Viscosity: Ranging from clear juices to thick nectars and purees, the vast differences in viscosity demand packaging equipment with broad adaptability.

| Item | Specification |

|---|---|

| Applicable Products | Various Liquids, Sauces |

| Pouch Width Range | 65 - 110 mm |

| Pouch Length Range | 100 - 230 mm |

| Filling Capacity | 5 - 100 grams |

| Packaging Speed | 60 - 90 bags / minute |

| Air Consumption | 0.7 m³ / minute |

| Bag Pick-up Method | Pneumatic Suction Cups (Requires Air Compressor) |

| Control System | Touchscreen + All-Servo Control |

| Machine Body Material | Food-Grade 304 Stainless Steel |

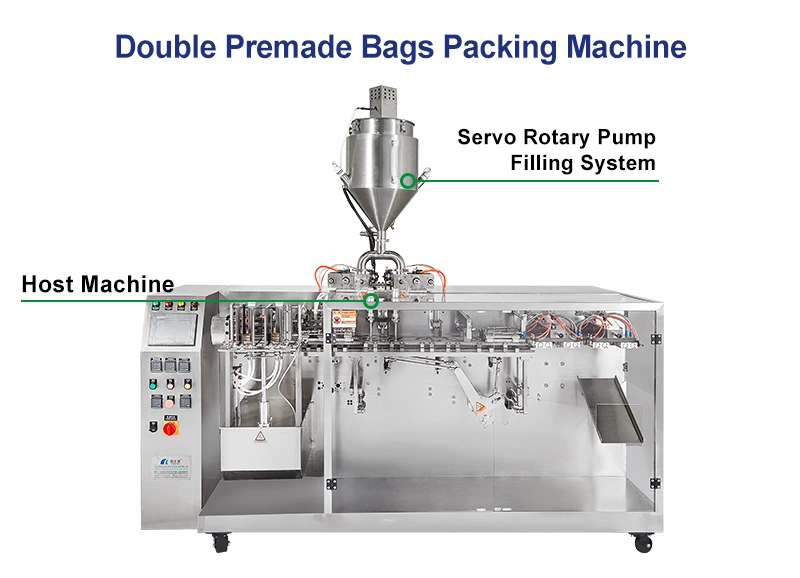

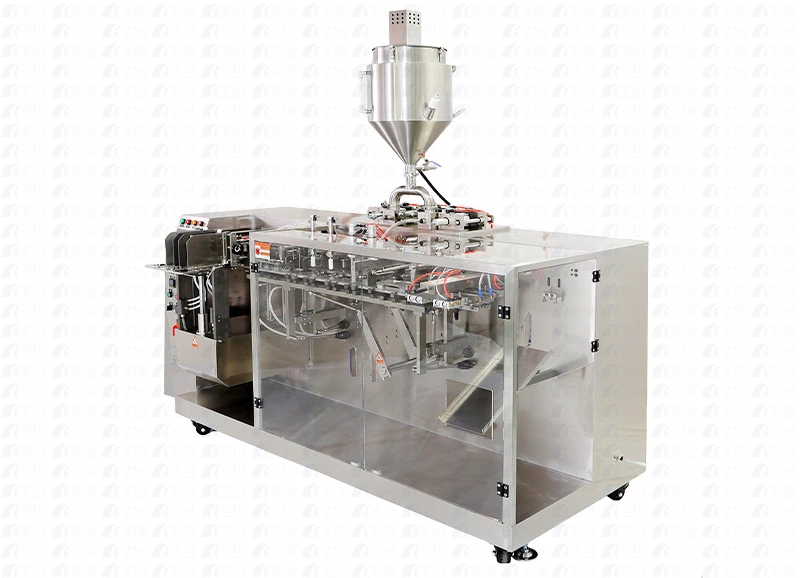

Horizontal double premade bags liguid packing machine

1. Food-Grade Materials & Robust Construction for Safety

The machine body is constructed entirely from food-grade 304 stainless steel, specifically designed to resist the corrosive nature of juice beverages. This material is not only safe and non-toxic but also offers excellent resistance to acids, alkalis, and rust. The smooth surfaces are easy to clean with no hard-to-reach areas, ensuring product safety from the source.

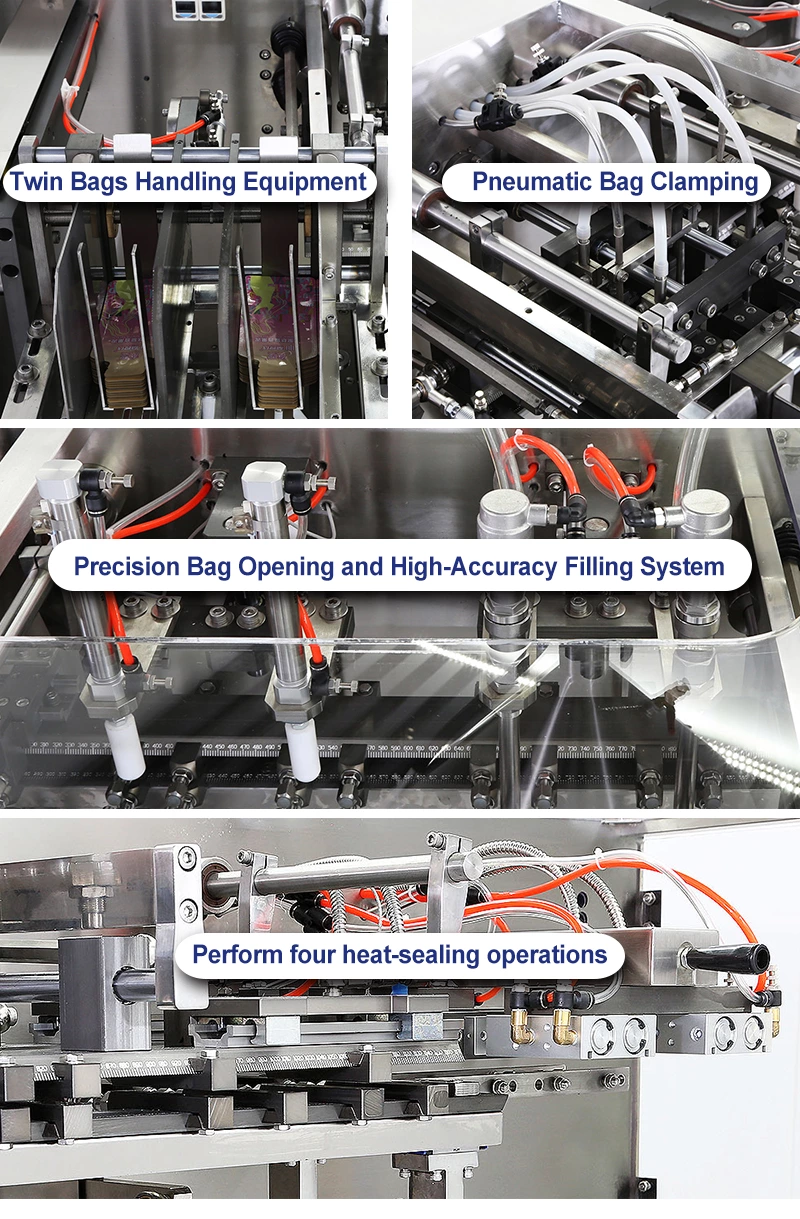

2. All-Servo Drive & Precision Filling for Efficiency & Quality

The transmission system utilizes all-servo motors, ensuring stable, jerk-free operation with noise levels significantly below industry average, effectively optimizing the production floor environment. By precisely controlling the coordination between the bag grippers, filling nozzles, and sealing mechanisms, it achieves seamless integration of all processes, greatly reducing the incidence of bag jams, leaks, and other failures. The filling mechanism is equipped with custom wear-resistant, anti-drip nozzles. These not only prevent chemical reactions with the juice, ensuring product purity, but also close instantly after filling, completely eliminating packaging contamination or equipment residue caused by liquid drips, maintaining a clean production environment.

3. Intelligent Temperature-Controlled Sealing & Visual Operation for Seal Integrity & Control

The sealing mechanism employs a patented dual heat-seal design. It can precisely adjust heating temperature and pressure parameters based on the thickness and material characteristics of different packaging films (like composite films, aluminum foil films), achieving uniform seals—clear, flat, strong, and tight. This minimizes the risk of seal splitting or leaks, effectively extending product shelf life. It features an intelligent control system with a high-definition touchscreen. The intuitive interface allows operators to quickly set parameters like fill volume, seal temperature, and packaging speed, while simultaneously monitoring the status of both production lines. A built-in intelligent fault alarm system triggers immediate audio-visual alerts and auto-stops the machine for issues like abnormal fill volume or excessive seal temperature, enabling quick troubleshooting and minimizing production losses.

Core Performance Advantages

-

Dual-Line Parallel Operation, Doubled Efficiency: Supports two packaging lines running simultaneously, with speeds reaching 60-90 bags/minute, significantly boosting output and meeting the volume demands of medium and large enterprises.

-

Low Consumption & High Stability, Easy Maintenance: Air consumption is only 0.7 m³/min, offering lower energy use than comparable equipment. The all-servo drive and high-quality components reduce failure rates and lower long-term maintenance costs.

-

Smart Adaptation & User-Friendly Operation: No specialized technical staff required; regular operators can manage the machine after brief training. The automatic fault停机 + alarm function reduces losses from operational errors.

-

Compliant Production, Peace of Mind: Food-grade materials and hygienic design ensure full compliance with food industry standards, facilitating smooth passage of regulatory inspections.

Adapting to Diverse Market Needs

This Horizontal Dual-Line Pouch Packager offers extensive pouch compatibility, meeting packaging needs for different market positions and consumer scenarios, helping businesses diversify their product offerings:

Standard Three-Side Seal Pouches: The classic pre-made pouch type, sealed on three sides with one side open for filling. Cost-effective and suitable for standard retail channels.

Stand-Up Pouches: Feature a gusseted bottom allowing them to stand upright after filling. Excellent for shelf display and convenient for consumer handling and storage.

Stand-Up Zipper Pouches: Include a resealable zipper for repeated sealing after opening, enhancing consumer experience and ideal for premium retail applications.

Four-Side Seal Flat Pouches: Fully sealed on all four sides, offering a regular shape and large, printable surface area perfect for highlighting branding and product benefits.

Shaped Pouches: Compatible with various unique shapes like rounded corners, curved edges, or bottle-like profiles.

Custom Services & Contact Information

Kunshida Machinery supports OEM customization services. We can tailor-make exclusive packaging solutions based on your specific production needs, such as special pouch adaptation, fill volume adjustment, or functional module upgrades.

If you have further inquiries or specific customization requirements, please feel free to contact us via email or our website message form!

Thank you for your interest and support. Kunshida Machinery is committed to providing you with high-quality products and professional service for a successful partnership

We can provide OEM custom packaging machine services. If needed, please email me or leave a message. Thank you for your time!

E-mail: info@ksdmachine.com

Phone: +86 13726511228

WhatsApp: +86 13726511228