The thriving juice industry has seen the continuous emergence of product categories such as NFC juice, cold-pressed juice, and composite fruit-and-vegetable juices, driving increasingly stringent market demands for packaging in terms of freshness preservation, portability, and hygiene. The unique physical and chemical properties of juice require its packaging equipment to be designed with specialized solutions. As a core solution tailored to juice packaging needs, the fully automatic spout pouch packaging machine has become the preferred choice for juice manufacturers, thanks to its efficiency, intelligence, and precision. This article will explore the key characteristics of juice and provide a comprehensive analysis of the machine’s core advantages, working principles, detailed design features, and compatible pouch types.

Juice Characteristics: Challenges Driving Packaging Machine Design

-

Susceptibility to Oxidation and Deterioration: Juice is rich in active components like vitamin C and natural pigments, which are highly sensitive to oxygen and light. UV light accelerates the decomposition of vitamin C and fades pigments, while oxygen leads to juice browning and flavor loss. Industry data indicates that improper packaging can result in a loss rate of up to 30% for nutrients like folate and anthocyanins.

-

High Fluidity and Risk of Leakage: With high water content and good fluidity, and some composite juices containing fruit pulp particles, juice demands extremely high packaging seal integrity. Inadequate sealing can easily cause leaks and may also promote microbial growth.

-

Stringent Hygiene Requirements: As a ready-to-drink food, the juice production and packaging process must avoid secondary contamination. All parts of the equipment contacting the juice must comply with food-grade hygiene standards and feature easy cleaning and sanitization capabilities.

-

Diverse Packaging Scenarios: Consumer demand highlights the need for portable juice packaging. Spout pouches are suitable for various consumption scenarios like outdoor activities, offices, and travel, requiring the packaging equipment to ensure a secure and reliable bond between the spout and the pouch body.

Comprehensive Overview of the Fully Automatic Spout Pouch Packaging Machine

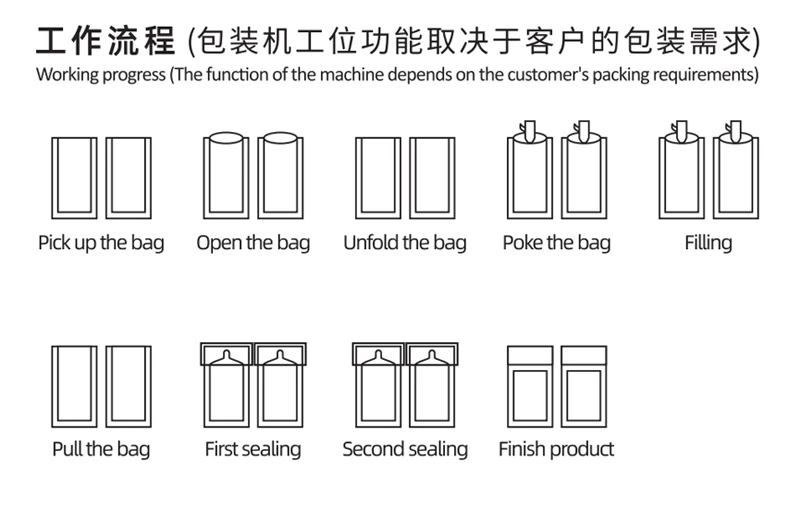

The machine operates with an 8-station process, completing tasks from pouch pickup, top/bottom opening, bag spreading, filling, indexing, performing two heat seals, to finished product conveyance in one continuous cycle.

-

Automated Pouch Feeding and Positioning: Utilizing vacuum suction cups, the machine precisely picks pre-made spout pouches from the storage area. Conveyed to the station via a belt, a photoelectric sensor detects the pouch mouth position in real-time, ensuring a pickup error of less than ±0.5mm and preventing misalignment in subsequent steps.

-

Precision Metering and Filling: Accounting for juice fluidity and potential particle content, a servo motor-controlled piston pump is employed for quantitative filling. A "drip-free mode" is activated during filling. After completion, the filling nozzle pauses for 0.5 seconds to control residual flow, preventing drips and contamination.

-

Machine Body Material and Structure: Constructed entirely from food-grade 304 stainless steel with a brushed surface finish for corrosion resistance and easy cleaning. The modular design separates the filling, sealing, and inspection zones, reducing cross-contamination risks and facilitating future maintenance.

-

Intelligent Control System: Equipped with a PLC control system and a color touchscreen. The user interface is intuitive, allowing real-time adjustment of parameters like packaging speed, fill volume, and sealing temperature. It supports production data logging and traceability. The system automatically alarms and displays fault reasons upon detection, lowering the operational skill barrier.

-

Sealing and Leak-Prevention Design: Features a dual heat-seal jaw structure where sealing pressure automatically adjusts based on pouch material thickness, ensuring consistent seal strength across different spout pouch materials. The filling nozzle employs a non-stick coating and is paired with a drip-free valve to prevent juice residue and bacterial growth.

-

Hygiene and Cleaning Functionality: Juice-contact parts such as the filling nozzle and hopper are designed for quick disassembly, enabling comprehensive cleaning and sanitization without complex manual teardown.

-

Adaptability and Details: The machine base includes adjustable leveling feet for easy calibration. Interfaces are预留 for devices like coders and checkweighers, allowing functional expansion based on customer needs for product traceability and quality control.

-

Pouch Type Compatibility (by structure): Compatible with stand-up spout pouches, shaped spout pouches, pouches with easy-tear notches, etc. Stand-up pouches enhance shelf display, while easy-tear features optimize consumer experience for on-the-go consumption.

Technical Specifications & Customization

This horizontal pre-made pouch packaging machine is compatible with pouches within the following ranges:

-

Pouch Width: 120 - 260 mm

-

Pouch Length: 100 - 350 mm

-

Fill Volume: 10 - 1000 g

-

Air Consumption: 0.4 m³/min

-

Pouch Types: Spout pouches, stand-up pouches, back-seal pouches, four-side-seal pouches, pillow pouches

A key advantage is operational flexibility: You can change the pouch size and type directly on the machine by simply adjusting the settings—no need for frequent mold or part changes.

We also provide OEM packaging machine customization services tailored to specific client requirements. Please feel free to contact us via email or our website message system. We are committed to designing the most suitable automatic packaging solution for your needs.

E-mail: info@ksdmachine.com

Phone: +86 13726511228

WhatsApp: +86 13726511228