Ketchup has a thick consistency and may contain tomato pulp particles. This requires the equipment to possess strong conveying and filling capabilities to prevent clogging and ensure consistent filling volume per pouch. As ketchup is an acidic food, prolonged contact can corrode the equipment's material-contact parts. Therefore, the packaging machine must be constructed from corrosion-resistant materials.

This equipment effectively addresses the challenges of automated ketchup packaging:

● The storage hopper features a built-in variable-frequency stirring device with heat retention functionality, preventing spoilage caused by prolonged exposure to air.

● Utilizing a servo high-precision rotary pump filling system, it achieves high-accuracy filling even with highly viscous ketchup, ensuring stable net content per pouch and reducing ketchup waste.

● It enables continuous bag picking, opening, filling, and sealing. With a speed of up to dozens of bags per minute, it significantly increases production capacity.

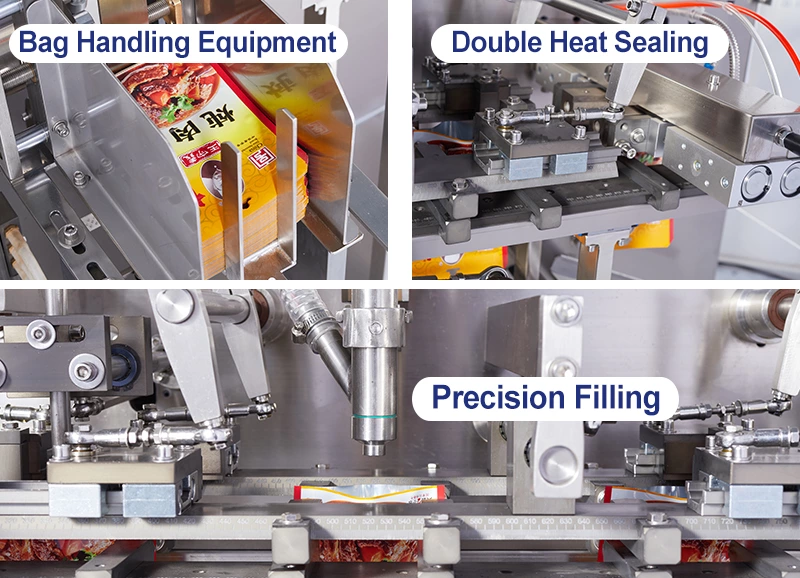

Regarding details, our packaging machine performs better than competitors: it includes an easy-to-adjust bag sizing mechanism, quantitative filling for ketchup, and a double heat-sealing process. This effectively mitigates issues of damage and leakage prone to occur during ketchup packaging and transportation.

Core Power System: Uses imported brand PLCs (Programmable Logic Controllers) and servo motors, ensuring stable and reliable operation, precise control, one-touch parameter adjustment, and facilitating quick switching between different packaging specifications.

Material Contact Parts: The material cylinder, filling valves, and conveying pipelines are all made from SUS304 stainless steel, offering corrosion resistance, easy cleaning, and compliance with international food hygiene standards.

User-Friendly Human-Machine Interface (HMI): A large color touchscreen provides intuitive and straightforward operation. Operators can easily set and store multiple recipes, greatly reducing setup and adjustment time.

Comprehensive Safety Protection: The equipment is equipped with multiple safety alarm systems (e.g., for missing bags, bag opening failure, filling abnormalities), ensuring smooth production line operation.

Wide Bag Compatibility: Compatible with common composite material stand-up bags such as AL foil bags, KPET/CPP, NY/PE, VMPET metallized bags, and can also accommodate custom bag types required by clients!

Standard Stand-up Bag: The most common bag type, stands stably, easy to display.

Stand-up Bag with Spout: Convenient for immediate consumption, especially suitable for outdoor, kitchen, and other lifestyle scenarios.

Shaped/Stand-up Bag: Features unique corner or bottom designs for novel shapes and high brand recognition.

Stand-up Bag with Zipper: Allows repeated sealing, maintains content freshness, and enhances user experience.(We can recommend suitable packaging machinery based on the client's actual bag type.)

This premade pouch packaging machine accommodates bag dimensions within a width range of 70-160 mm and a length range of 100-260 mm. The filling capacity range is 5-500 ml. Packaging speed ranges from 30 to 60 bags per minute. Air consumption is 0.7³/min. It uses pneumatic suction cups for bag grasping and requires an air compressor for operation.

We can provide OEM custom packaging machine services. If needed, please email me or leave a message. Thank you for your time!

E-mail: info@ksdmachine.com

Phone: +86 13726511228

WhatsApp: +86 13726511228